Ship seals, often referred to as marine seals or shipboard seals, are essential components used in various applications and systems on ships and vessels. These seals play a crucial role in maintaining the integrity and functionality of a ship, ensuring safety, preventing leaks, and protecting equipment and cargo. Here’s an overview of ship seals and their applications:

Key Functions and Types of Ship Seals:

- Watertight Seals: Watertight seals are designed to prevent the ingress of water into a ship’s compartments, holds, or other areas, ensuring buoyancy and stability. These seals are essential for the ship’s safety and operation.

- Weather Seals: Weather seals are used to prevent the entry of rain, seawater spray, and harsh weather elements into specific ship compartments, including cabins and cargo areas.

- Hatch Seals: Hatch seals are used on cargo holds to create a tight seal between the hatch covers and the hatch coaming, preventing water and weather from entering and protecting the cargo from moisture and contamination.

- Shaft Seals: Shaft seals, such as stern tube seals and stuffing box seals, are used to prevent water from entering the ship through the shaft openings where propellers, drive shafts, or propulsion systems pass through the hull.

- Bulkhead Seals: Bulkhead seals are used to maintain the watertight integrity of bulkheads (dividing walls within a ship) to prevent water from spreading in the event of damage or flooding.

- Porthole and Window Seals: Seals around portholes and windows are used to prevent water and weather infiltration while maintaining visibility from inside the ship.

Materials and Design:

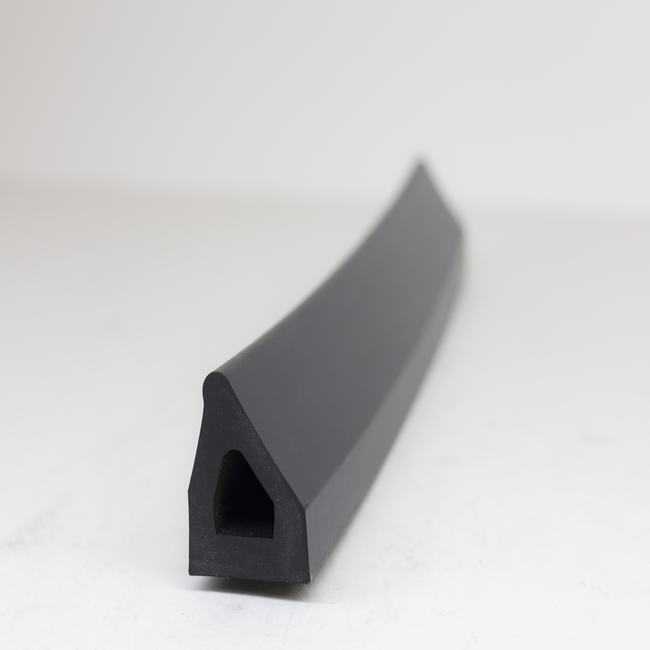

Ship seals are made from a variety of materials depending on their intended use and environmental conditions. Common materials include rubber compounds, elastomers, neoprene, EPDM (Ethylene Propylene Diene Monomer), and other synthetic materials that offer resistance to saltwater, UV exposure, and temperature variations. The design of ship seals ensures a secure fit, durability, and resistance to corrosion.

Installation and Maintenance:

Proper installation of ship seals is critical for their effectiveness. Installation procedures vary depending on the type of seal and its location. Regular maintenance and inspections are also essential to detect wear, damage, or deterioration. Damaged seals should be promptly replaced or repaired to maintain the ship’s integrity and safety.

Applications:

Ship seals are used in various marine applications, including:

- Cargo Vessels: Ensuring the integrity of hatch seals is crucial for the safe transport of cargo in bulk carriers, container ships, and general cargo vessels.

- Passenger Ships: Weather seals and window seals in passenger ships like cruise liners and ferries enhance passenger comfort and safety.

- Naval and Military Vessels: Watertight seals are critical for naval vessels, submarines, and military ships to withstand harsh marine environments and combat conditions.

- Offshore Platforms: Seals are used in offshore oil and gas platforms to maintain watertight integrity and prevent water ingress.

- Fishing Vessels: Seals protect fishing vessels from seawater and weather, ensuring the preservation of the catch.

In conclusion, ship seals are essential components of marine systems, ensuring the safety, functionality, and integrity of ships and vessels. Proper selection, installation, and maintenance of ship seals are vital for safe and efficient maritime operations.