Concrete pipe seals, also known as concrete pipe gaskets or seals for concrete pipes, are specialized components used to create a watertight and secure connection between concrete pipes in various piping systems. These seals are essential for preventing leakage, ensuring the structural integrity of the pipeline, and protecting against the infiltration of soil, groundwater, or other materials. Here’s an overview of concrete pipe seals:

Key Functions:

- Sealing: The primary function of concrete pipe seals is to provide a watertight seal between the joints of concrete pipes, preventing the escape of fluids from within the pipeline and preventing the intrusion of external elements.

- Structural Integrity: Concrete pipe seals also contribute to the structural stability of the pipeline by ensuring that the pipes are securely connected. This helps prevent pipe misalignment and displacement.

- Preventing Contamination: By creating a barrier against external contaminants such as soil, silt, and groundwater, concrete pipe seals help maintain the quality of the transported fluids and prevent contamination.

Types of Concrete Pipe Seals:

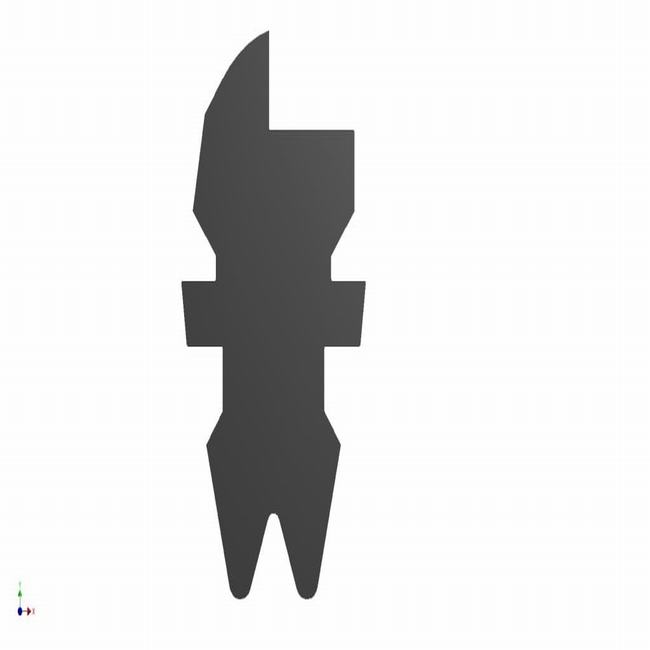

- Rubber Gaskets: Rubber gaskets are commonly used as seals for concrete pipes. They are typically made from materials such as EPDM (Ethylene Propylene Diene Monomer) rubber, neoprene rubber, or natural rubber. These gaskets are designed to fit into the groove or recess provided in the concrete pipe joint and create a compression seal when the pipes are connected.

- Lubricated Gaskets: Some concrete pipe seals come pre-lubricated with a special lubricant or grease that aids in the installation process. This lubrication reduces friction and facilitates the proper compression of the seal during joint assembly.

- O-Ring Seals: O-ring seals are circular seals made from rubber or elastomeric materials and are used in specific types of concrete pipe joints to create a tight seal.

Installation and Maintenance:

Proper installation of concrete pipe seals is crucial to ensure their effectiveness. Key installation steps include:

- Cleaning the pipe ends and the seal groove to remove any debris.

- Ensuring that the seal is properly aligned within the groove.

- Applying the necessary lubrication if using lubricated gaskets.

- Compressing the seal adequately during joint assembly.

Maintenance primarily involves inspecting the seals for wear, damage, or signs of deterioration. Damaged or worn seals should be replaced promptly to maintain the integrity of the pipeline.

Applications:

Concrete pipe seals are used in various applications and industries, including:

- Wastewater and Sewer Systems: Concrete pipe seals are essential for sewage and wastewater pipelines to prevent leaks and contamination of the surrounding soil.

- Stormwater Drainage: In stormwater management systems, these seals help control the flow of stormwater and prevent soil erosion.

- Water Supply Infrastructure: Concrete pipes with proper seals are used in water supply systems to transport potable water safely.

- Culverts and Bridges: Culverts made of concrete pipes with seals facilitate the flow of water under roads and bridges.

- Irrigation Systems: Concrete pipes and seals are used in agricultural irrigation systems to convey water to fields.

In conclusion, concrete pipe seals are critical components in various piping systems, ensuring the integrity and functionality of the pipelines by providing effective sealing, preventing leaks, and protecting against contamination. Proper installation and maintenance are essential for their long-term performance.