PVC (Polyvinyl Chloride) pipe seals are crucial components used in the installation and maintenance of PVC pipelines. PVC pipes are widely used in various applications due to their durability, corrosion resistance, and affordability. PVC pipe seals play a pivotal role in ensuring the integrity and longevity of the pipeline system. Here is an overview of PVC pipe seals:

1. Purpose and Function:

PVC pipe seals are designed to create a secure and watertight seal at joints, connections, and fittings within PVC pipelines. Their primary functions include:

- Preventing leakage of liquids or gases transported within the pipeline.

- Isolating different sections of the pipeline to control flow or facilitate maintenance.

- Compensating for irregularities or variations in pipe dimensions and ensuring a snug fit.

- Reducing the risk of contamination or infiltration from external sources.

2. Materials:

PVC pipe seals are typically made from materials compatible with PVC pipes and the transported fluids. Common materials used for PVC pipe seals include:

- EPDM (Ethylene Propylene Diene Monomer): EPDM rubber is known for its excellent weathering resistance, chemical resistance, and durability, making it suitable for various applications.

- Nitrile Rubber (NBR): NBR rubber is chosen for its oil and fuel resistance, making it suitable for pipelines that transport hydrocarbons.

- PVC: In some cases, PVC gaskets or seals made from the same material as the pipe are used for simplicity and compatibility.

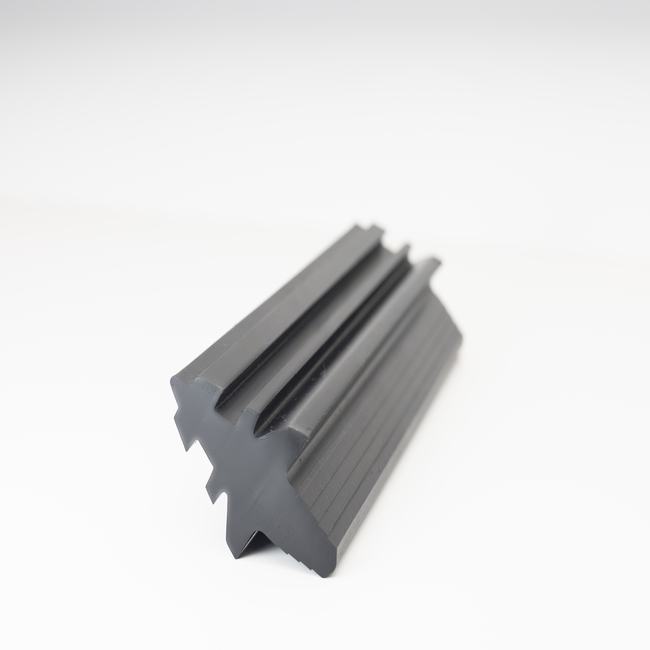

3. Types of PVC Pipe Seals:

Several types of PVC pipe seals are designed for different applications within PVC pipelines, including:

- Flange gaskets: These gaskets are used between pipe flanges to create a seal and secure the connection.

- Joint seals: Designed to seal the joints between two sections of PVC pipes.

- Expansion joints: Provide flexibility to accommodate thermal expansion and contraction in the pipeline.

- Compression seals: Used to compensate for slight variations in pipe dimensions during installation.

- End caps and plugs: These are used to seal pipe ends or openings that are not currently in use.

4. Installation and Maintenance:

Proper installation of PVC pipe seals is critical to ensure their effectiveness. Installation typically involves cleaning and preparing the surfaces, applying lubricants or sealants as needed, and following manufacturer’s guidelines.

Regular inspection and maintenance of the seals are also essential to identify and address wear, damage, or deterioration over time. Replacing seals as part of a preventive maintenance program helps prevent unexpected leaks and ensures the reliability of the PVC pipeline.

In conclusion, PVC pipe seals are essential components in PVC pipeline systems, providing sealing solutions to prevent leaks, maintain pipeline integrity, and ensure efficient fluid transport. Proper material selection, installation, and maintenance are key factors in the performance and durability of these seals.