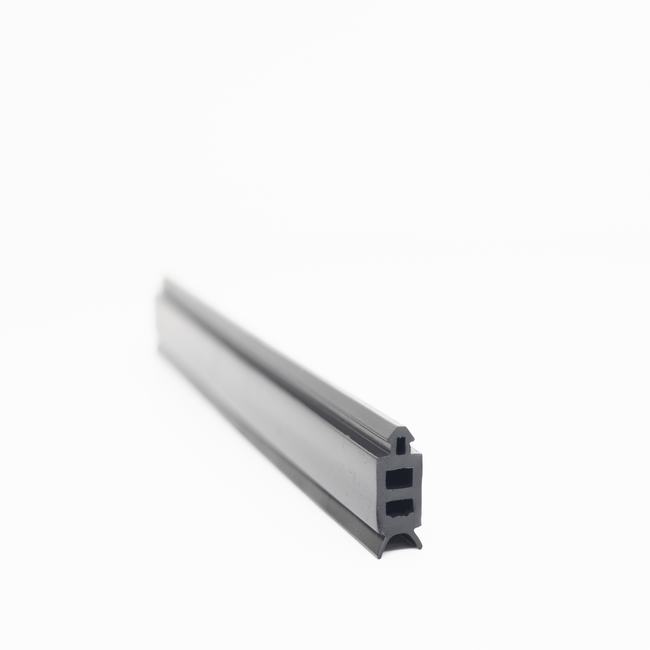

EPDM (Ethylene Propylene Diene Monomer) rubber seals, also known as EPDM gaskets or EPDM rubber sealing strips, are versatile components used to create effective seals in a wide range of industrial, commercial, and residential applications. EPDM rubber is a synthetic elastomer known for its excellent weather resistance, durability, and flexibility. EPDM rubber seals are valued for their ability to provide watertight seals, prevent leaks, and protect against environmental factors. Here’s an overview of EPDM rubber seals:

Key Features and Advantages:

- Weather Resistance: EPDM rubber is highly resistant to UV radiation, ozone, and extreme weather conditions, making it ideal for outdoor and exposed applications.

- Temperature Tolerance: EPDM rubber maintains its flexibility and sealing properties over a wide temperature range, from extremely cold to moderately hot conditions.

- Chemical Resistance: EPDM rubber offers good resistance to many chemicals, including acids, alkalis, and various solvents. It is also compatible with water and steam.

- Durability: EPDM rubber seals are known for their long service life and resistance to degradation, making them suitable for applications that require extended use.

- Flexibility: EPDM rubber is highly flexible and can conform to irregular surfaces, ensuring a tight seal even on uneven or rough substrates.

- Electrical Insulation: EPDM rubber has excellent electrical insulation properties, making it suitable for electrical enclosures, gaskets, and seals.

Common Applications:

EPDM rubber seals find applications in various industries and settings, including:

- Automotive: EPDM rubber seals are used in automotive applications, including door seals, window seals, gaskets, and weatherstripping, due to their resistance to heat and weathering.

- Construction: EPDM gaskets and seals are employed in construction for window seals, roofing membranes, door seals, and weatherstripping to create watertight and airtight seals.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM rubber seals are used in HVAC systems for sealing ducts, vents, and access panels to prevent air leakage.

- Electrical Enclosures: EPDM rubber gaskets provide electrical insulation and environmental sealing in electrical enclosures, control cabinets, and junction boxes.

- Plumbing: EPDM rubber gaskets are used in plumbing applications for sealing pipe connections, faucets, valves, and plumbing fixtures to prevent water leaks.

- Marine: EPDM gaskets and seals are employed in marine applications for sealing hatches, portholes, and other openings to prevent water ingress.

- Industrial Equipment: EPDM rubber seals are used in various industrial equipment for sealing enclosures, access panels, machinery, and conveyor systems.

Customization and Design:

EPDM rubber seals can be customized in terms of size, shape, and thickness to meet specific application requirements. They are available in various forms, including extruded gaskets, molded gaskets, flat gaskets, and o-ring gaskets. The design and material composition can be tailored to the specific environmental conditions and sealing demands of each application.

In conclusion, EPDM rubber seals are highly versatile and valued for their exceptional weather resistance, durability, and flexibility. They are essential components in many industries and applications where reliable sealing and protection against environmental factors are crucial. Proper selection, installation, and maintenance of EPDM rubber seals are essential for ensuring effective sealing and long-lasting performance.